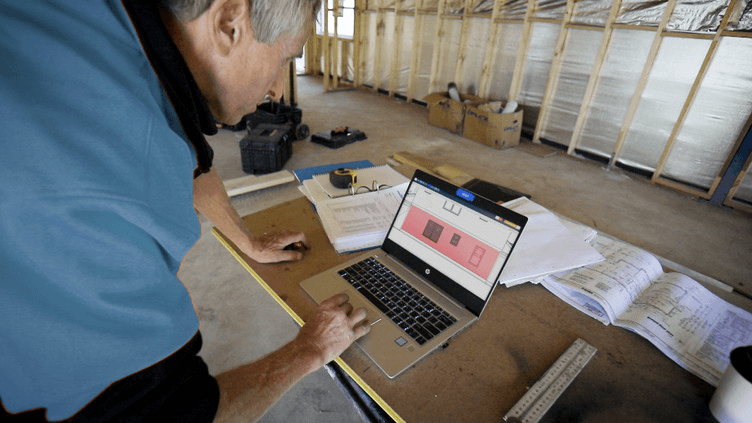

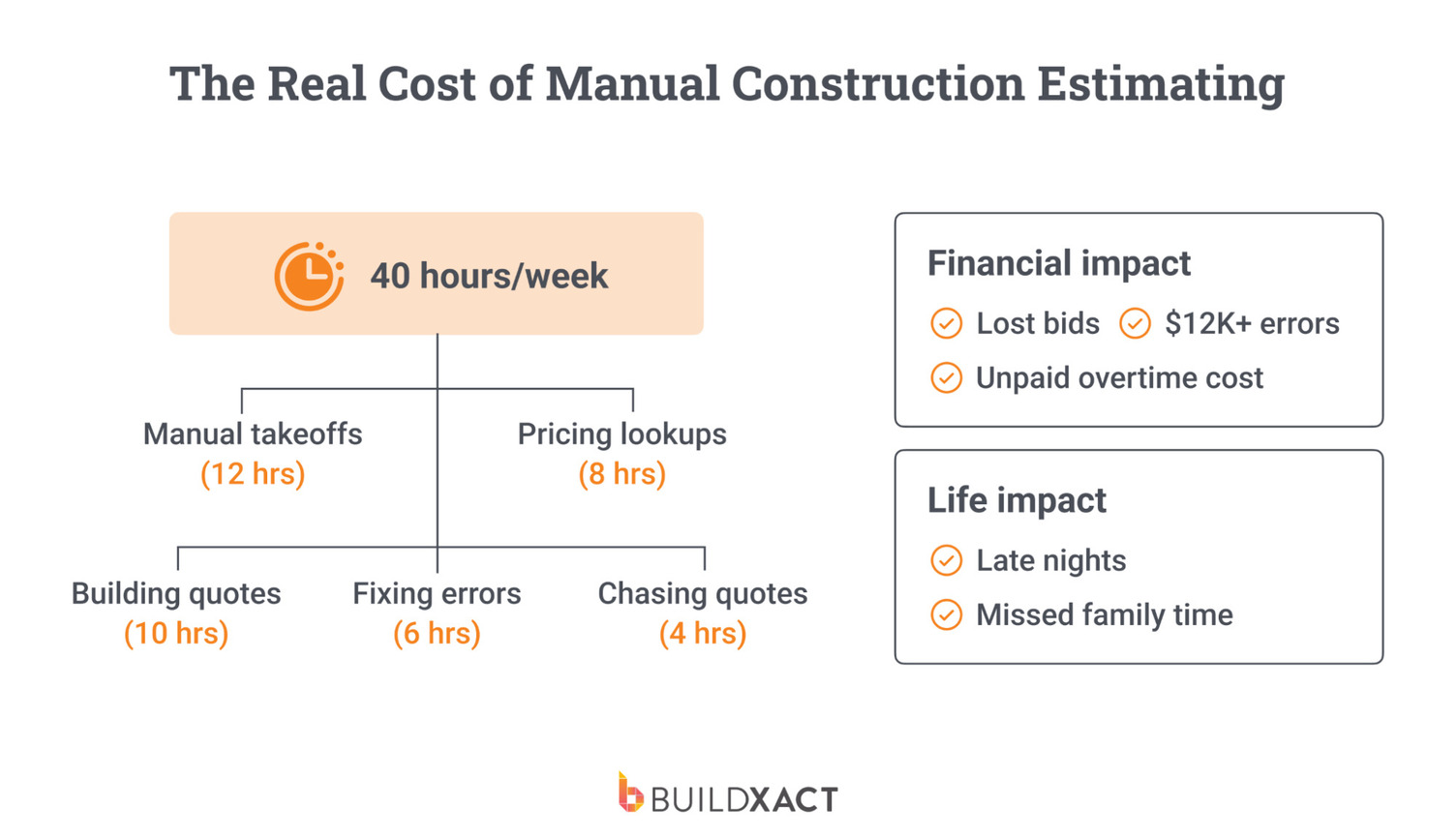

For many small home builders, the work doesn’t stop when the jobsite shuts down.

Evenings often mean sitting back down to compare prices from different dealers, creating bids from scratch, and piecing together estimates that you didn’t have time to review during the day.

It’s hours of unpaid construction estimating work done late at night, under pressure, and often alone.

The result?

- Bids are often submitted late, while competitors send theirs within hours.

- Errors creep in when you’re rushing at 2 am.

- Forgotten materials can add up to thousands of dollars in lost margin.

- You lose bids not because your price is wrong, but because your bid arrived too late.

It doesn’t have to be this hard.

This guide shows small residential builders how to reduce the time spent estimating per project. You’ll learn the 8-step estimating process that protects your margins, plus how purpose-built estimating tools eliminate the manual work that’s keeping you at your desk until 2 am.

What is Construction Estimating?

Construction estimating is the process of calculating all costs required to complete a building project before work begins: materials, labor, equipment, permits, and overhead.

- For small residential builders, this means determining accurate costs for projects like kitchen remodels, bathroom renovations, home extensions, and custom builds. Estimates can track materials related to these projects, such as trim, fasteners, hardware, and silicone.

- For commercial estimators, this entails managing fewer, but larger, line items across major phases.

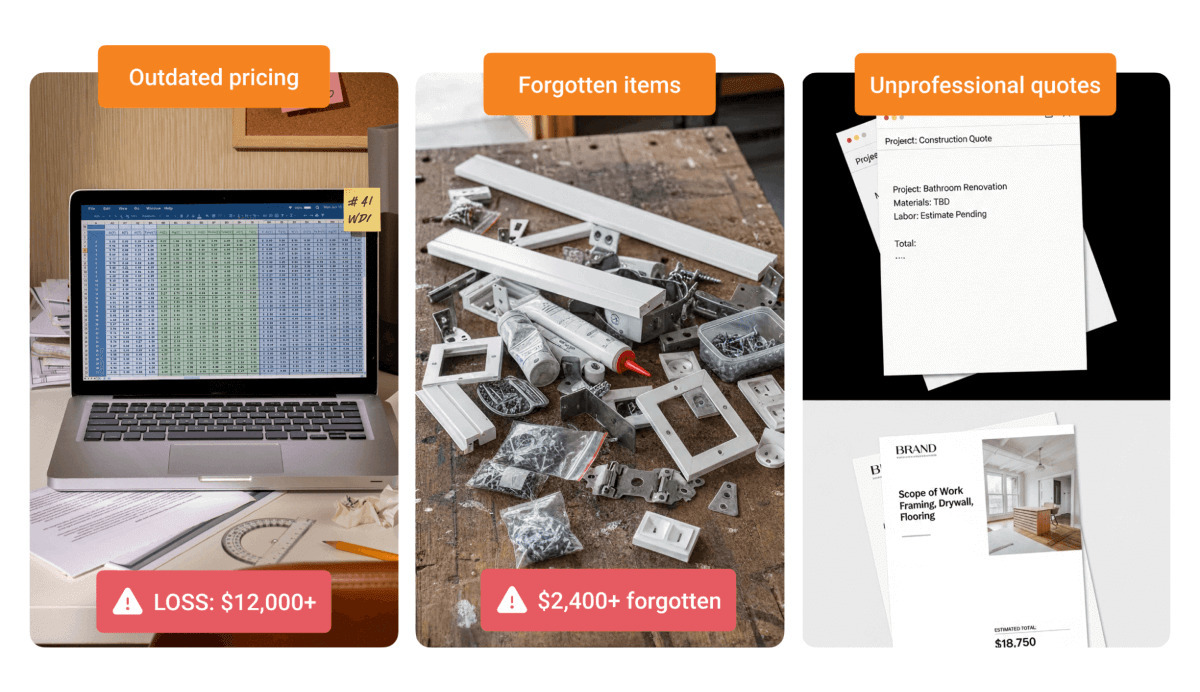

Get the estimate right, and you can bid competitively while protecting your margins. If you get it wrong by missing a wax ring here, or forgetting drawer slides on three vanities there, pricing lumber from last month’s quote, those gaps add up to thousands of dollars lost per job.

6 Common Construction Estimating Mistakes

Consistently catching them before you submit a bid requires a system, not just effort.

Without that system, you might win jobs, but somewhere between the signed contract and the final invoice, the margin disappears.

It’s rarely one big mistake. More often, it’s a series of minor estimating errors that accumulate within a system that isn’t designed to catch them.

These six mistakes reveal where estimating systems most commonly break down and what that breakdown actually costs.

Mistake 1: Underestimating labor and productivity

FMI’s 2023 Labor Productivity Study found 60% of contractors waste 11% or more of field labor costs.

That loss doesn’t come from a single bad call. It shows up when labor is priced for how a job should run, not how it actually does. The estimate assumes a tight crew moving straight through the work, but the job might start a day late, be split across different people, or slow down because materials aren’t yet staged.

Time spent setting up, waiting, redoing small tasks, or cleaning up at the end of the day is rarely billed, even though crews still get paid for it. Without a way to compare estimated hours to what really happened on site, those same assumptions quietly carry into the next bid.

To address this long-term, you’ll need to price for the crew you’ll actually have, which means tracking actual hours against estimated hours on completed jobs and then using those numbers for the next bid.

Mistake 2: Inaccurate material and supply cost estimates

Many builders rely on prices from their last job, numbers that are often 60–90 days old by the time a new estimate goes out. By the time the quote goes out, the numbers are stale, and you’re locking in a job that might lose money.

Keith Perez of TXN Remodeling Construction ran into this exact problem. He was quoting $4.99 for a 2×4 when the real price had already jumped to $6.99, a 41% miss on every stick of lumber.

What Keith was experiencing on-site is an example of a much larger issue and proves how very industry-wide changes can affect even small- and medium-sized residential builders and remodelers.

That’s why it’s crucial to plan for and incorporate resilience into your operations, systems, and teams now.

Deloitte’s 2026 Engineering and Construction Industry Outlook analysis found that rising material costs are a response to multiple factors — namely, tariffs, supply chain disruptions, and even talent/labor shortfalls.

The solution is building dynamic pricing into your estimating process with tools that enable you to:

- Request fresh dealer quotes before every bid.

- Include escalation clauses for long-lead jobs.

- Add a buffer for waste and returns.

Mistake 3: Omitting overhead, indirect, and contingency costs

Indirect costs often slip through because no checklist compels you to account for them. Permits, insurance, supervision, and dumpster rental don’t require the same attention as materials and labor do. So they’re invisible until they surface mid-project.

Jaime Hommerding of XPRES Kitchen and Bath was writing them off as “not a big deal.” Then he started tracking the numbers, and the picture they painted was hurting his bottom line:

$800 to $2,500 per job, which went toward soft costs that he hadn’t priced.

Those gaps aren’t limited to just one job, either. Across the industry, construction projects consistently run 28% over budget, and unaccounted soft costs are a leading cause.

Some builders keep a master list of indirect costs by project type to avoid obvious misses. That approach works until the job changes. When scope shifts, selections evolve, or timelines stretch, those soft costs don’t update automatically.

In other words, someone has to remember to add them back in.

Builders only gain full control over overhead and contingencies when they’re able to build those costs directly into the estimate, so that job changes reflect every other connected aspect.

Mistake 4: Ignoring site and scope conditions

Estimating doesn’t just price materials and labor. It assumes a specific way the job will run. That assumption breaks down when site conditions don’t match the plans. It could result in all-too-common situations:

- A cramped lot limits staging.

- Street parking forces crews to haul materials farther.

- Out-of-square walls in an older home turn “standard framing” into custom cuts, which the estimate never accounted for.

When an estimator misses these details, the estimate describes a project that doesn’t exist. Crews still perform the work, and the gap reappears as change orders, delays, and lost margin.

That’s why Steve Griffin from Just Building Group, walks every site before he prices a job. His team used to lose change orders to paper plans, desk assumptions, and missed handoffs.

Now he documents access, storage, utilities, and demolition scope upfront so the estimate reflects how the job will actually run.

“When they see the level of detail, it blows their mind,” he says. “They rarely come back with questions.”

Fewer questions upfront prevent surprises mid-project. Thirty minutes on site often saves hours of change-order negotiations because the information captured there sets the baseline for every subsequent decision.

Mistake 5: Poor documentation and communication

By the time most estimates are complete, project information is scattered across too many places.

- A work breakdown sits in a spreadsheet.

- Updated numbers hide in an email thread, and notes from a phone call never make it into the file.

- A client change request arrives via text and disappears.

Each detail made sense at the moment, but when a question comes up, no single record answers it.

Joshua Bradley of BradWay Construction saw this pattern inside his own business:

“It just became like four or five places where I was keeping this information.”

Those “four or five places” create real cost. Teams waste time hunting for the latest version, reconciling conflicting information, and re-explaining decisions that have already been made. The work slows down not because anyone failed to communicate, but because no system held the whole picture.

When project information lives in one place, those problems shrink. Teams catch errors earlier, answer questions faster, and resolve scope issues before they reach the client. A single source of truth turns memory and guesswork into documented fact.

Mistake 6: Disconnected systems and unscalable processes

The first five mistakes happen inside individual estimates. However, they all point to a deeper issue: estimating, costing, and project tracking aren’t connected into a single, repeatable process.

Here’s what that looks like in practice:

- Takeoffs live in one place.

- Pricing sits in a spreadsheet.

- Job costing is lagging behind receipts and bank statements.

In short, each step is siloed.

And while you’re unlikely to notice this disconnect at a low volume of business, your growth and success goals will reveal the cracks in your current systems and processes, ultimately leading to missed costs, delayed decisions, and estimates that drift from reality.

Keith Perez of TXN Remodeling & Construction felt that friction before he changed his approach.

“I can see my profit and loss per job, labor percentage, material lists, and purchase orders in one view.”

These six mistakes share a common root cause: Disconnected estimating, costing, and project tracking that turn small gaps into expensive problems.

Reliable estimates come from working harder or double-checking numbers. They follow the same sequence every time, so nothing depends on memory or heroics.

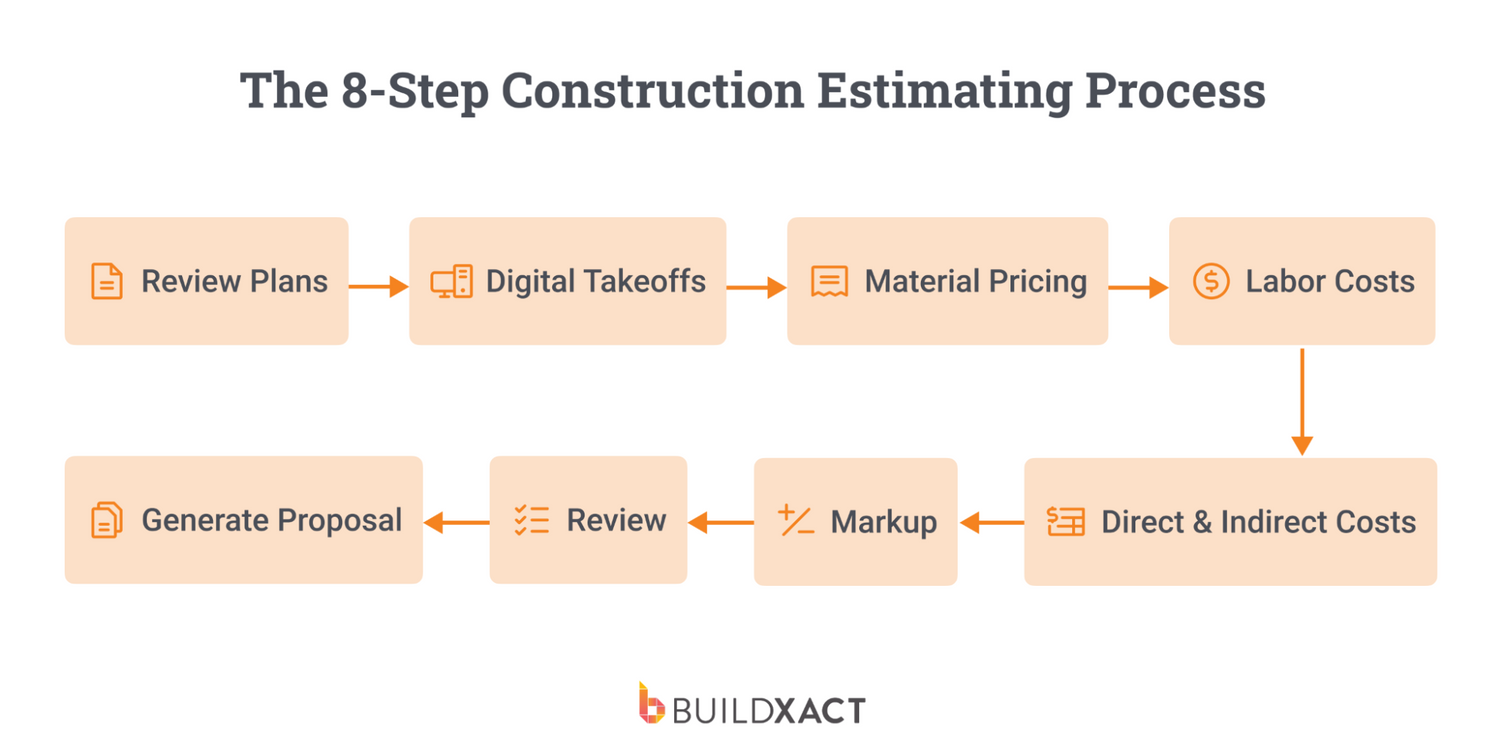

8 Steps to Accurate Construction Estimating

The 2025 SORCI Report found that 47% of builders have a documented process, and the gap is wider for estimating. Without a repeatable system, estimators rely on memory, which leads to missed items, inconsistent pricing, and progressively eroding margins.

These eight steps outline a documented estimating system for you to follow.

On their own, the steps aren’t new; what makes them work is having software in place to support them. Without tools to connect plans, takeoffs, pricing, labor, and revisions, even the best process falls back on memory and manual effort.

Step 1: Review project plans and specifications

Every estimate starts with plans, but plans rarely show every detail. Appliance selections stay open. Fixture specifications go missing. If those gaps remain informal or are noted in side notes, estimating becomes guesswork, and guesswork becomes change orders once the job begins.

Accurate estimating depends on capturing missing selections, open-ended scope items, and site constraints early and ensuring they carry through the entire estimate, rather than relying on memory or assumptions.

Before you price an estimate, three things need to happen:

- Convert unknowns into allowances: Achieve price flexibility without compromising margins, and document every assumption so that scope changes remain visible as selections evolve.

- Walk the site before final numbers: A change in ceiling height affects framing, electrical, drywall, and painting. A site visit reveals access limitations, utility locations, demolition scope, and structural conditions that the plans don’t show.

- Capture everything in one project record: Plans, site notes, allowances, and assumptions should be kept together so that missing details remain attached to the estimate as it evolves, rather than getting lost between emails, notebooks, and spreadsheets.

Buildxact supports this by allowing builders to upload plans directly to the project file and attach notes, allowances, and assumptions in one place, ensuring that early decisions and constraints are carried through pricing instead of being rediscovered mid-project.

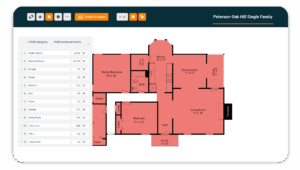

Step 2: Perform digital quantity takeoffs

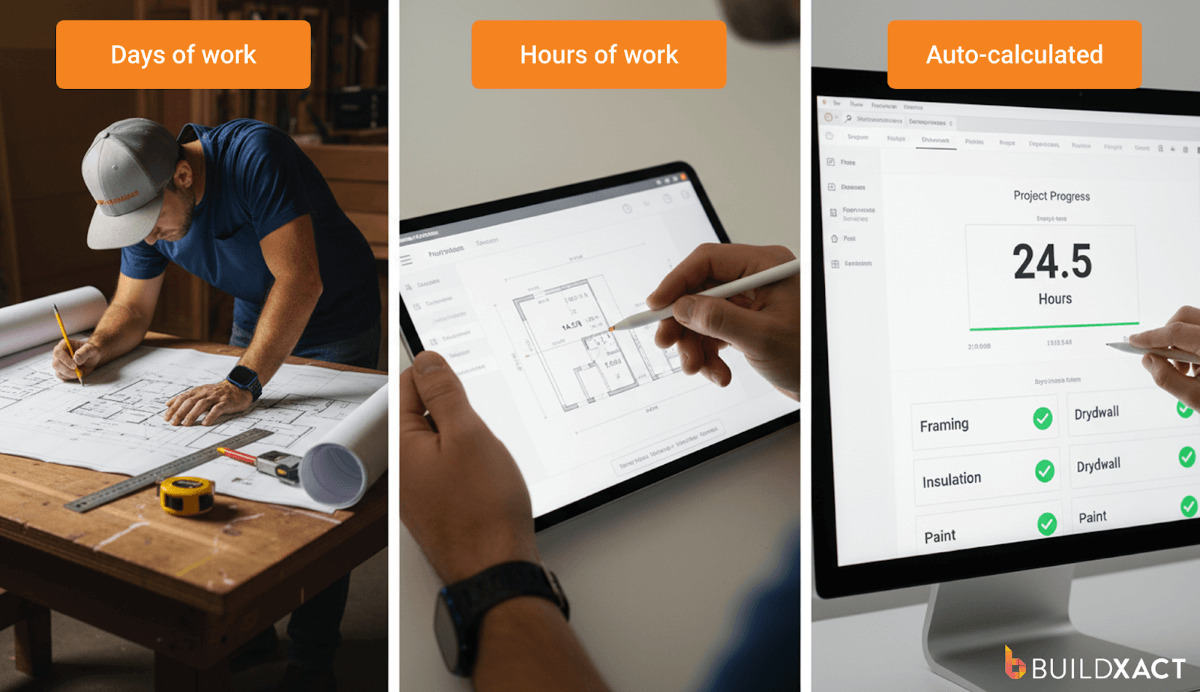

Takeoffs repeat the same motion: measure, apply scale, record quantities, then repeat the process.

Because those quantities feed pricing, labor, and scope across the entire estimate, manual takeoffs break down once changes start, and numbers need to stay in sync.

Digitize your quantity takeoff process by uploading plans once, measuring directly on the drawing, and letting quantities sync across all related materials without re-entry. The logic stays the same, but the math updates automatically instead of relying on manual accuracy.

Buildxact supports this by allowing PDF plan uploads with click-to-measure takeoffs. Blu: Takeoff Assistant automates scaling and measurements. For jobs without plans, Rendr creates floor plans using a phone camera.

Using takeoff software can help builders compress their process from days into hours, which means estimating isn’t the bottleneck anymore — it becomes their competitive edge.

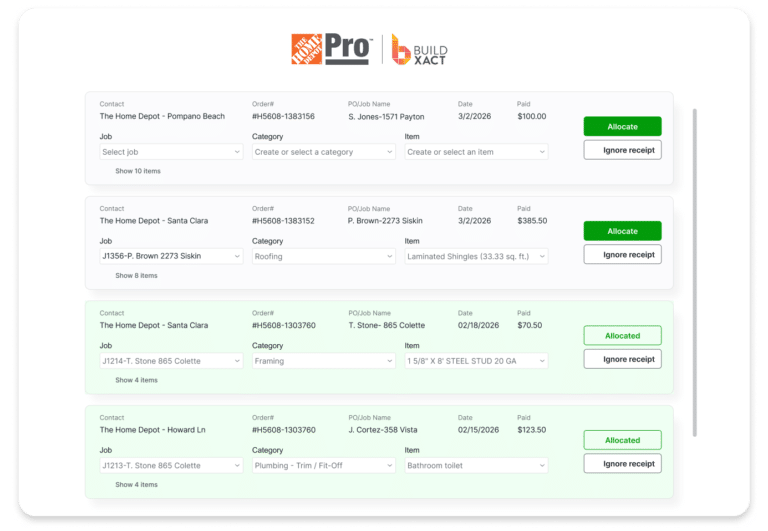

Step 3: Apply current material pricing

Keeping material pricing current means incorporating updates into the estimating process rather than checking numbers after the fact. However, the process becomes protracted, as it typically involves pulling fresh dealer quotes, accounting for long lead times, and allowing for real-world waste, breakage, and returns.

Buildxact supports this by syncing dealer price lists directly into estimates. A single refresh updates material costs across all line items, eliminating the need for manual lookups and addressing the consequences of outdated pricing.

Accurate pricing protects margin before the contract is signed — when it still can.

Step 4: Integrate labor data into your estimates

Labor is often the largest line item in a residential estimate, and the one most likely to drift from pricing to completion.

Productivity varies by skill level. A lead carpenter works faster than an apprentice on the same task, yet estimates often price both at a single blended rate. A one-day task on paper typically expands into more paid hours once payroll taxes, insurance, and overtime are factored in.

That gap exists because labor data is rarely visible in the estimating process once work moves to the field. Recording hours alone isn’t enough if that information lives in timesheets, job logs, or payroll reports that never inform future estimates.

Recording on-site activity by task across completed jobs shows where time consistently runs long, where crews move faster, and where estimates miss.

Buildxact lets builders define labor rates by trade and capture on-site job activity through task updates and daily logs, which carry back into future estimates.

Over time, labor pricing reflects how crews actually work rather than relying on industry averages.

Step 5: Include all direct and indirect costs

Indirect costs like permits, dumpster fees, and temporary utilities slip through because the estimate organizes work by trades and tasks, not overhead.

To address this issue, Buildxact offers “recipes,” which connect directly to takeoff measurements. They bundle related items into a single selection: for example, a wall assembly recipe includes studs, sheathing, insulation, drywall, and paint.

Using the pre-defined recipe in the estimate ensures that every component is included.

Check out our walkthrough below recipes (also known as assemblies) work: a single takeoff unifies materials and labor, updates automatically, and carries forward into future estimates.

Step 6: Add markup for overhead and profit

Markup covers overhead and profit, but the real challenge is applying the right margin to the right parts of a job. Different scopes carry different levels of risk.

A project with locked selections and short lead times doesn’t deserve the same margin as a remodel where scope evolves, demolition defines the work, and material pricing can change midstream.

Builders default to a “one-size-fits-all” approach to margins because manually adjusting markup across jobs, scopes, and phases is difficult to maintain under real-world workload and time pressure. Blanket margins hold together operationally even when they leave money on the table or absorb risk unnecessarily.

Buildxact lets builders apply markup at the item, category, or project level, making those adjustments deliberate rather than reactive. Instead of forcing one margin across the entire estimate, you can apply markup exactly where uncertainty lives and protect profit without slowing down the estimating process.

Step 7: Review for completeness and accuracy

Builders who catch errors consistently review estimates in two passes. The first pass checks the math: quantities, unit costs, extensions, and totals.

The second pass checks completeness by trade. Does electrical include panel upgrades and plumbing include fixture installation?

The problem is that most builders estimate on their own, and reviews often occur late at night, when attention wanes, and the bid needs to be submitted in the morning. There’s rarely a second set of eyes available to run that completeness check.

Buildxact’s Blu: Estimate Reviewer acts as that second pass. It scans the estimate against patterns from similar projects and flags common omissions and inconsistencies before the bid goes out. The review runs every time, even when no one else is available to check your estimate.

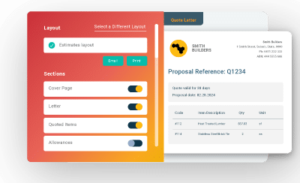

Step 8: Generate professional proposals

When the estimate comes together behind the scenes, your client sees a robust, transparent, and logical proposal.

Strong proposals matter because they:

- Set expectations early by outlining the total investment and timeline before presenting the line items.

- Break down the scope by phase and highlight key material selections, making it clear where the budget is allocated.

- Present information in a structure that eliminates assumptions and reduces disputes that start with, “I thought that was included.”

Buildxact generates proposals directly from estimate data, ensuring that pricing, scope, and branding are carried through without rework. Clients approve digitally, and the signed proposal stays attached to the project alongside the estimate.

Turn Construction Estimating into Time You Can Reinvest in Growing the Business

Manually building estimates across spreadsheets, dealer emails, and paper plans requires working nights and weekends. Each bid pulls you back into repetitive work: re-measuring drawings, re-checking prices, reconciling notes, and chasing missing details. Not because estimating is difficult, but because the process is fragmented.

A connected estimating system powered by Buildxact changes that. When takeoffs, pricing, labor, markups, and proposals live in one place, estimating becomes repeatable instead of reactive. Information is carried forward automatically, fewer decisions depend on memory, and fewer errors surface after the bid is submitted.

If you’re ready to build accurate estimates faster and protect your margins as you grow, get started for free today or book an interactive demo.