If you’ve ever finished a residential build thinking, “We should’ve made more on that,” the issue wasn’t obvious while the job was running.

The estimate covered labor and materials, the work followed the scope, and the client was satisfied. Then you reconcile the costs, and the numbers don’t add up.

That gap rarely comes from a single major mistake. More often, it’s small misses: a change approved but never priced, a dealer cost that shifts after the quote, or materials that seem insignificant and aren’t tracked.

The response is usually to put increased effort: re-checking estimates, reviewing costs mid-job, and tightening oversight next time. But it’s better visibility tied to strategy, not more effort, that fixes the core problem.

Without visibility into where costs diverge from the estimate, it’s hard to see where the drift actually begins. However, incorporating strategies like lean construction with visibility can help you reduce waste and improve workflow.

This article examines what that looks like in residential work — and how you can use software to adopt these best practices, seeing gains in your bottom line, right away.

What is Lean Construction When Applied to Residential Building Projects?

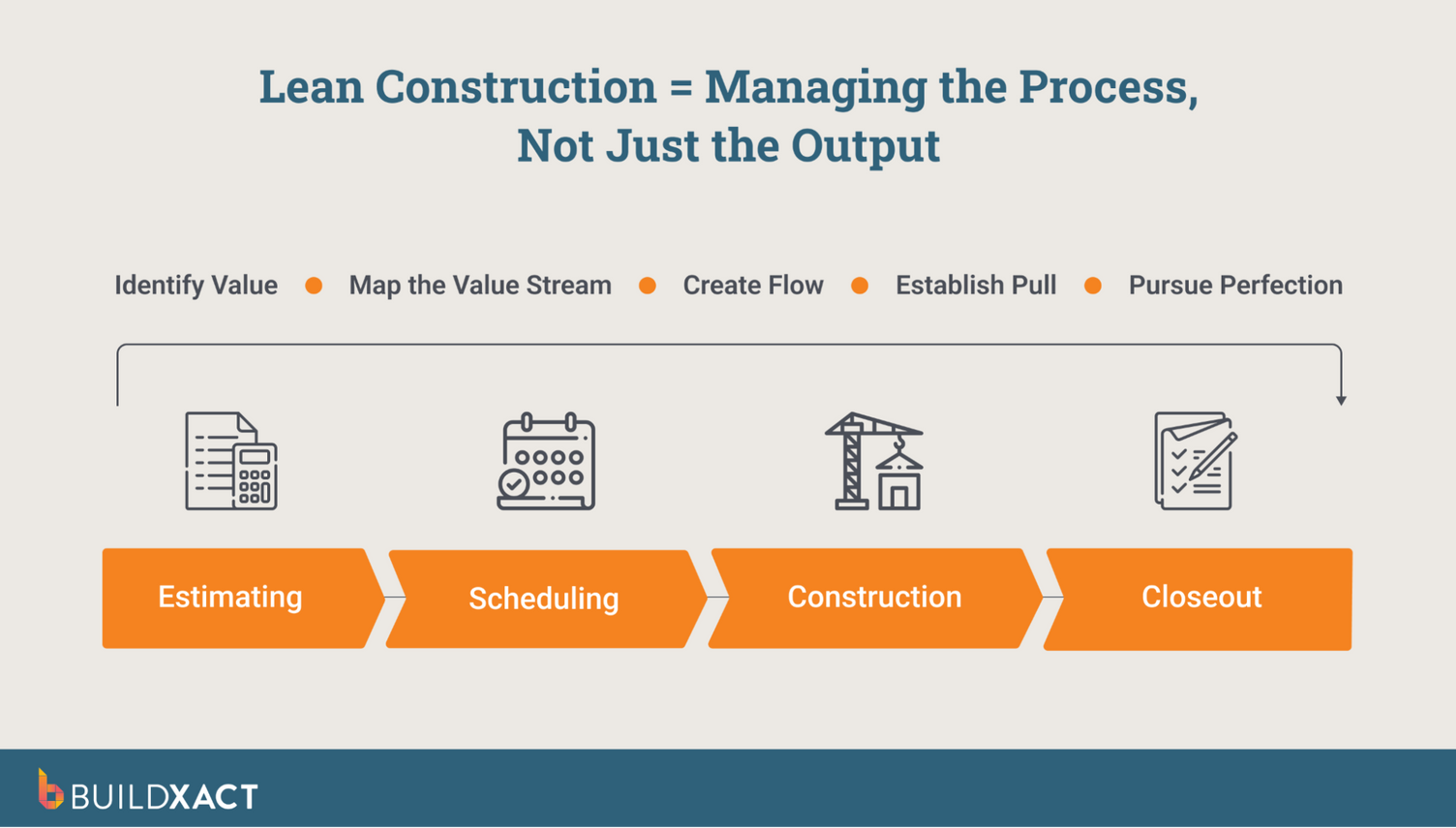

Despite the name, “lean construction,” the approach isn’t about cutting corners or moving faster for the sake of speed. In residential building, it’s about maintaining control as work and information change, all without introducing additional friction.

Lean principles applied to residential construction help builders eliminate waste by ensuring that the correct information reaches the right people at the right time.

And that matters in residential projects because progress rarely follows a straight line:

- Estimates are approved, then refined.

- Site conditions surface new details. Supplier pricing shifts.

- Clients make small decisions that quietly alter scope and sequencing.

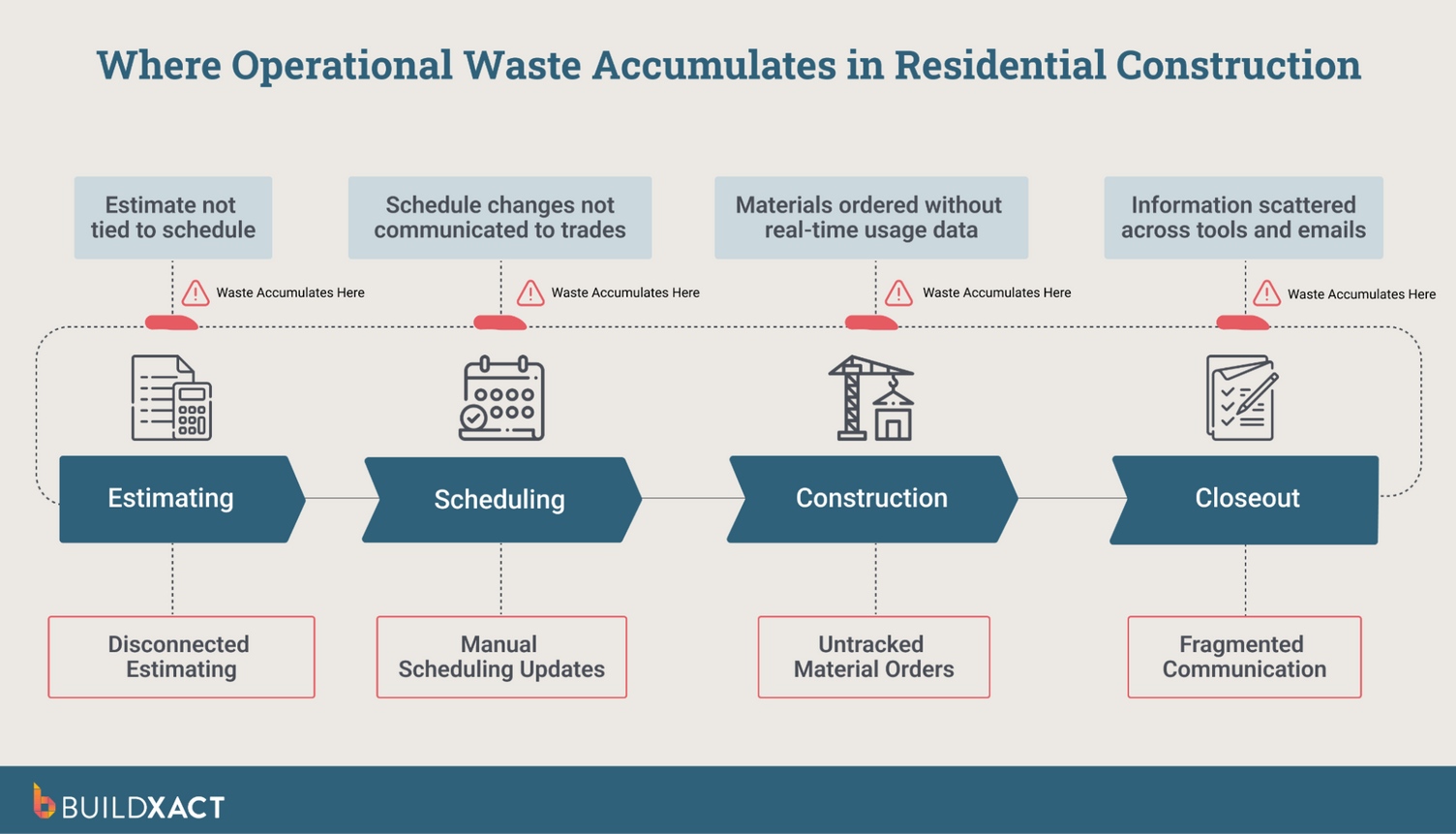

Each of those moments introduces change. And when those changes aren’t captured, reconciled, or shared clearly, waste creeps in — not as inefficiency on site, but as confusion, rework, missed costs, and reactive decision-making.

Using lean principles and software designed to support this approach, builders can observe work in real-time, identify issues early, and adjust processes before small disconnects become delays or margin loss.

For residential builders, lean construction provides a practical framework for doing exactly that: making work visible, managing variation, and continuously improving how jobs are planned and delivered.

The following five principles outline how lean construction applies in real residential workflows — and the “gaps” that lurk as opportunities for builders who want to implement these principles for more effective processes.

5 lean construction principles for residential builders

Lean construction works or breaks based on whether estimated decisions still show up after site changes, pricing shifts, and invoicing.

We’ll examine how common residential building issues create the very gaps that lean principles can help builders address and seal.

1. Identify value

Value often breaks at the quote.

You send a lump sum, the client asks for a breakdown, and pulling line items back out takes time you don’t have. The total goes out without detail. The scope stays the same, but the client never fully sees what they are paying for.

This slows down approvals and sharpens scrutiny as selections and change requests begin to come in.

2. Map the value stream

In the weeks leading up to a job’s start, selections change, prices are revised, and clarifications are received through various channels.

One decision is conveyed in an email reply, another in an attachment, and yet another in marked-up plans. By kickoff, you are no longer working from a single estimate version. When questions arise, the delay is not in answering them, but in determining where the answer last resided.

3. Create flow

During a site walk, the client approves a layout change to an office. The site lead gives the go-ahead, and the crew builds it that week. No one updates the estimate, flags the supervisor, or notifies the dealer.

When the invoice goes out at the end of the phase, the change is missing from the budget, and the client disputes the amount while the team scrambles to reconstruct what the client approved.

4. Establish pull

In the days before ordering materials, prices change faster than your estimate can keep up with. One figure comes from a dealer list saved weeks ago, another from a recent phone call, another from memory.

To maintain the original start date, you approve the order using the best number available at that time. When the dealer invoice comes in higher, the estimate stays unchanged. With no revised estimate or approved variation to reference, you absorb the difference directly in the job margin.

5. Pursue perfection

While reviewing final job costs, you notice the same misses again. Sealants, fasteners, and small finishing items are listed on invoices but not included in the estimate. Each one felt insignificant while bidding, so you moved on.

When the next estimate starts, you reuse the same template and miss the same items again. The realization repeats from job to job, but nothing in the estimating process changes.

How the 8 Wastes of Lean Construction Show Up on Residential Jobs

Lean construction groups these patterns into eight types of waste. What matters is recognizing how they show up in residential work, which is often long before anything looks wrong.

| Waste type | What it looks like in residential work | How it shows up on residential jobs | Impact on the job | System conditions |

| Transportation | Materials were moved multiple times before installation. | Deliveries arrive too early or to the wrong area; materials are shifted to make space. | Lost time, damaged materials, crew inefficiency. | Purchasing, scheduling, and delivery timing aren’t coordinated. |

| Inventory | Materials are ordered well before they’re needed. | Lumber, fixtures, or finishes stored on-site “just in case.” | Cash tied up; storage risk; discrepancies at reconciliation. | Ordering decisions aren’t tied to install timing or live quantities. |

| Motion | Crews spend time searching instead of working. | Walking across the site for tools, specs, or answers. | Lost productivity; fatigue; avoidable mistakes. | Information and tools aren’t accessible where work happens. |

| Waiting | Work pauses because something upstream isn’t ready. | Crews are left waiting on specs, inspections, or prior trades. | Paid labor doing nothing; schedule slippage. | Dependencies aren’t visible; schedule changes don’t propagate. |

| Overprocessing | Extra effort that doesn’t improve the outcome. | Redundant documentation; approvals no one uses | Higher soft costs; slower progress. | No clear signal for what information actually needs to be captured. |

| Overproduction | Extra work is completed, but either before it’s required or proves irrelevant. | Phases completed early; documents created “just in case.” | Rework; misalignment between trades. | Estimating, scheduling, and execution aren’t sequenced together. |

| Defects (Rework) | Work has to be redone due to misalignment. | Built to the wrong spec; failed inspections; client disputes. | Double labor and materials; client frustration | Decisions and changes aren’t tracked to a single source of truth. |

| Unused talent | Team knowledge isn’t captured or reused. | Field insights are often ignored, and the owner becomes the bottleneck. | Missed improvements; slower delivery. | No consistent way to capture learning or delegate decisions. |

Each of these lean construction wastes can be traced back to the same root: decisions made in one place that don’t carry forward to the next. The fix is to close the gaps where information drops off — without adding to your workload.

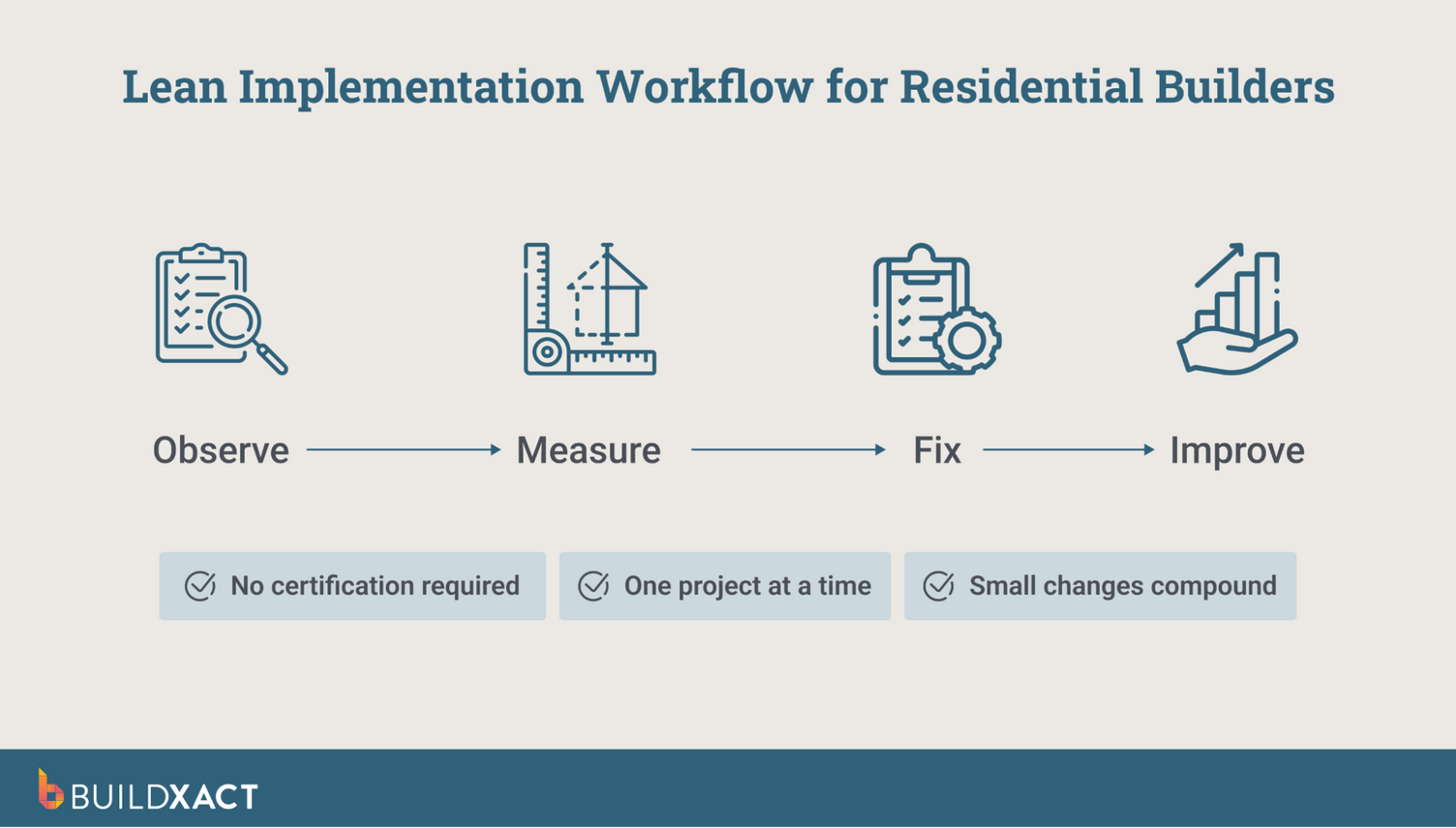

How to Apply Lean Construction on a Residential Build

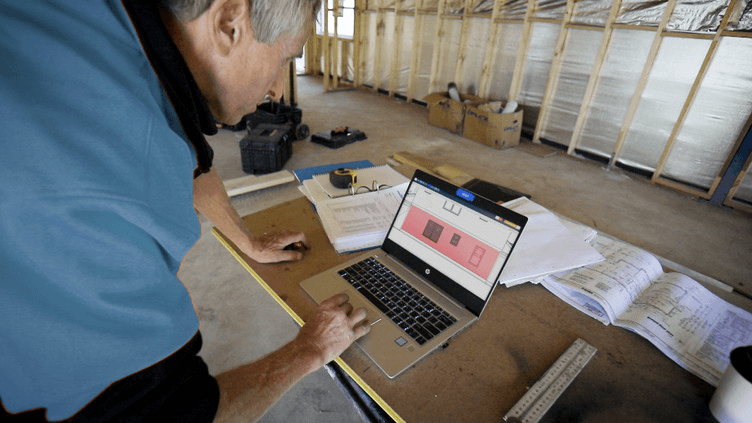

On a residential build, you apply lean while work is already moving, and across decision-making touchpoints, such as estimating, selection, or site changes. These are disconnected from essential functions, such as pricing, purchasing, and invoicing.

Through a step-wise process, we’ll show you how residential builders rely on lean implementation and software solutions to maintain and manage a truly connected residential building ecosystem.

1. Watch the work (make “waste” visible in real-time)

On most residential builds, work rarely comes to a complete halt. Instead:

- A crew waits for clarification.

- Someone walks the site searching for drawings that someone sent.

- A question comes up that already has an answer somewhere.

- Each pause feels small enough to work around, so no one flags it. It’s likely not even visible if your teams and tools are disconnected.

Josh Vendramini of VW Building Projects described how this problem surfaced after hours, once site work ended, but paperwork remained unfinished. He spent evenings translating marked-up plans back into numbers and retracing decisions that should not have required reconstruction.

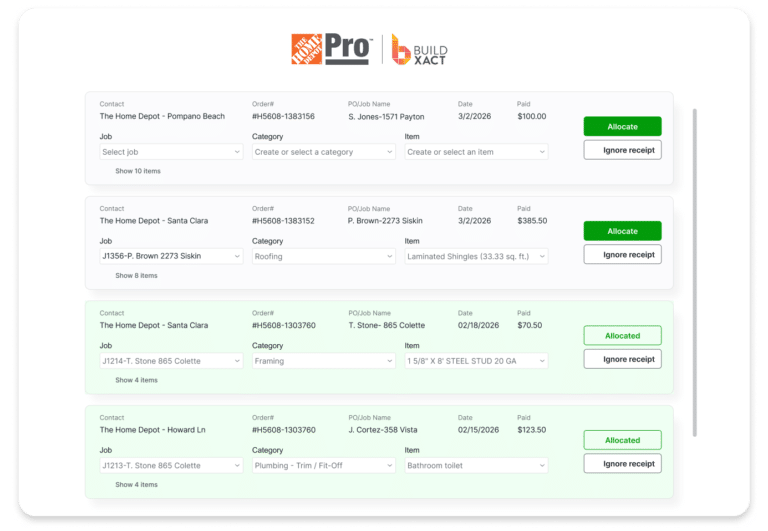

However, when software features enable builders to ensure that estimated data flows directly into the job budget, spend stays tied to what you’ve priced out, and this makes slowdowns visible even as hobs progress.

2. Measure only one waste area (make the hidden visible)

Margin erosion is an ideal place to start when addressing “waste” — not only can you reduce the issues contributing to loss, but you can boost that margin when addressing the correct problems.

Here’s what it could look like:

- A dealer changes a price after the estimate has been sent out.

- A crew adjusts a quantity mid-project.

- An allowance stretches further than expected. Each adjustment feels manageable on its own, so the builder parks it.

- Later, the job finishes, but the numbers don’t line up.

So, what happened? As Keith Perez of TXN Remodeling & Construction experienced in his own business, it wasn’t a failure because the estimate was wrong — it was the process. It wasn’t set up and supported by tools designed to detect the drift while it was happening.

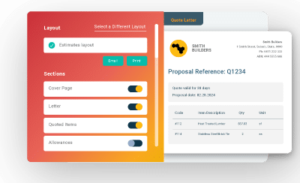

However, when construction project budgets are drawn directly from the estimate, as they are in Buildxact, material costs remain in the same workspace as quantities, orders, and totals.

3. Fix one process (small changes, immediate wins)

Fixes on residential jobs don’t fail because they lack merit. They fail because approved changes don’t make it through the handoff from site work to the next estimate.

A client approves a change on-site. The crew adjusts and keeps moving. Nothing feels broken. However, the decision is often conveyed in a conversation, a text, or marked-up plans. When you start the next estimate, that context is gone, and the same blind spot reappears.

This is the one process where minor fixes often disappear: how you record, price, and carry forward approved changes. Builders don’t ignore these decisions. They reset them without realizing it.

In Buildxact, variations are directly connected to financial tools and information, such as estimates and budgets, ensuring that job changes and your bottom line remain aligned and update automatically.

4. Build from there (lean is continuous improvement)

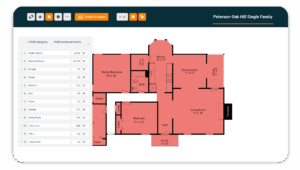

One way to prevent the same estimating gaps from reappearing is by grouping frequently reused materials and details using assemblies that you can then carry forward from job to job:

Small items like sealants, fixings, or finish details stop appearing as surprises — not because you remembered better this time, but because you accounted for them earlier.

That change shows up at closeout. You spend less time explaining why the numbers moved and less time retracing decisions to figure out where money went.

This is how lean compounds in residential work. Learning carries forward instead of resetting, and each new estimate starts closer to reality than the last.

This pattern also appears in formal lean research. Teams that stabilize their plans early and track whether weekly commitments are complete see clearer performance improvements long before a project closes out. Projects that improve early vary less and recover faster when things change.

Keep Decisions Connected From Estimate to Closeout

Applying lean to a residential build comes down to whether decisions stay connected from estimate to closeout. When quantities, pricing, and changes are updated in one place, you stop reconstructing context at the end of the job and start managing costs while the work is still underway.

Buildxact supports this by keeping estimating, budgeting, and job costs aligned as the project progresses. That means less time chasing information, fewer gaps at closeout, and estimates that reflect what actually happened on the last job.

To see what that looks like with a real estimate, including how changes and assemblies carry forward from job to job, get started for free or book a demo to walk through it with your own estimate.