It doesn’t matter whether you prefer to call it material takeoff, construction takeoff or estimation takeoff, a quantity takeoff is an essential part of any building project. Whether it is a large or a small job, accurate quantity takeoffs can mean the difference between a financial disaster and a completed project that keeps everyone happy.

What is a quantity takeoff in construction?

In construction, a quantity takeoff is a list of all the physical materials necessary to complete a job and their costs. It does not consider labor costs, permits, overheads, equipment, or other incidentals. ‘Takeoff’ refers to taking information off blueprints, drawings, or models and ‘quantity’ refers to the amount of materials.

Difference between materials and quantity takeoff

Every door knob, floor tile, hinge, pipe, carpeting, length of steel, insulation, or any other fitting must be included in a material quantity takeoff list. Different materials are measured or counted differently, but everything needs to be converted into a cost estimate.

Why is it important to do a quantity takeoff?

Construction projects require a lot of time and money. For them to be profitable, every cost must be accounted for and included in the overall price. Suppose an accurate construction quantity takeoff hasn’t been performed. If that’s the case, then you might find yourself overbudget and out of pocket. Overestimating can result in you losing bids.

During what stage should a quantity takeoff be completed?

The quantity takeoff should be done early in the process, before offering any quotes or bids. Without one, you won’t know what your profit is or if you will be making a loss. Your material quantity takeoff may have to be redone several times as changes are made, to ensure a good profit margin remains and your clients are happy.

Who is responsible for doing a project’s quantity takeoff?

Anyone in charge of a project that requires materials needs to perform a quantity takeoff. A baker needs to consider the cost of ingredients when quoting the price of a wedding cake. In construction, builders, estimators, architects, engineers and construction managers must ensure they are allowing for the right amount of materials and their costs within the project budget.

What measurements are required?

When manufacturers make a product, they sell them in the way most appropriate for the product. For example, you don’t buy a length of nails or a box of timber. So, you must measure the various materials in different ways. You cannot count drywall like you count doorknobs, nor do you determine carpet size in the same way you calculate how much piping you need.

Unit count

Items like lights, pipe fittings, hinges, doors, or power points are materials counted in units. With items like nails, a unit consists of 500 or a unit can be an individual object, like air conditioners, or windows. Sometimes the same item can come in different sizes, which usually have their own costs. This means the items need to be tallied up in their own size and cost group.

Linear length

Although you can count pipes, electrical wiring, or pieces of steel, suppliers sell them according to length. So, you have to calculate the amount by the linear length.

Surface area

To calculate the amount of material to cover an area, like carpet, the space’s length and width is multiplied to find the surface area. This process is used when taking off roof quantities.

Cubic volume

When filling space, such as with concrete or blow-in insulation, the measurements required are length x width x height. This calculation will result in the cubic volume of the material, allowing you to calculate its cost estimation accurately.

Physical weight

Materials like sand or backfill come in weight measurements, such as a ton of sand. They are usually purchased in a standard amount and an overestimation is needed to ensure enough quantity is ordered.

How to do a quantity takeoff – the basics

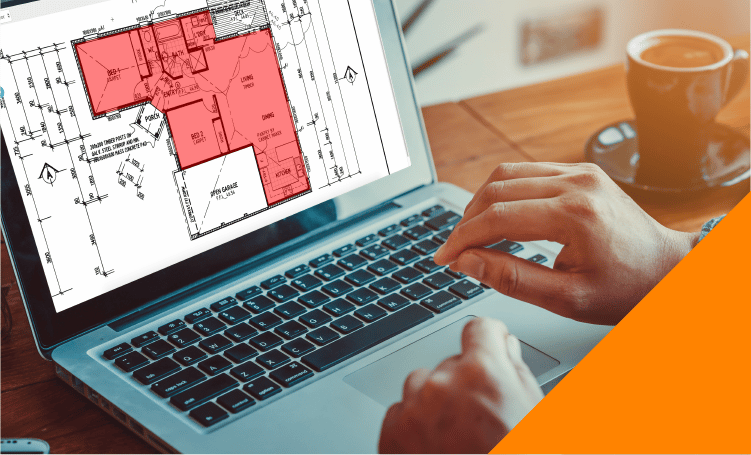

Preparing a quantity takeoff involves converting blueprints into data or taking off quantities from drawings. It begins with counting the materials the project needs and converting them into a cost, which is then used in creating a quote or it can be used to calculate the project’s budget. The first step is to understand what materials are needed for the project and then to quantify them.

Understand what needs to be counted

You, your estimator, or Quantity Surveyor must count every item that is sold in units and list them. For example, 1 reverse-cycle air conditioner, 3 boxes of roofing nails, or 12 silver doorknobs.

Take measurements

It is the same for materials that are bought by length, weight, area, or volume, they need to be measured, priced, and the calculation added to the material takeoff list.

Calculate the takeoff

Once the material quantity takeoff list is completed the data must be converted into a dollar amount. This means knowing how much the supplier charges for each item, or the cost per length, weight, or by volume and calculating the cost by quantity. The prices of doorknobs can vary greatly depending on the quality and style of the product. So, detailed descriptions and accurate pricing is crucial in creating a precise quantity takeoff. Buying 30 plain doorknobs at $17 each is greatly different to 30 locking doorknobs at $45 each. One simple pricing error like this would put the budget out by $840. So, you can imagine the blowout if we weren’t talking doorknobs, but something really expensive or you repeatedly miss materials. Detail and accuracy are key to a quantity takeoff.

Different types of quantity takeoffs

There used to be only one way of performing a quantity takeoff and that was manually. A skilled Quantity Surveyor would assess the materials needed, formulate a cost, and they would pick up on any mistakes or issues along the way. However, advancements in technology have improved the efficiency of quantity takeoffs, making the process a lot quicker and improving its accuracy.

Manual quantity takeoff

A manual quantity takeoff relies on the knowledge and skills of the person performing it. When they are retrieving the quantity takeoff data from a drawing or blueprint, they must convert the pictures into 3D in their mind. They have to be creative and critical thinkers to perform this process. Takeoff quantity surveying is time-consuming if it is to be detailed and accurate. Anything rushed could be missing quantities or issues may not be identified. The Quantity Surveyor cannot miss any materials, items, or quantities if they do the project budget will be out. They also need to have good knowledge of the product price, quantity discounts, and any other variables that can alter the overall costs.

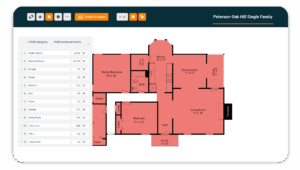

Digital quantity takeoff

Today, there is estimation software to help produce a quality quantity takeoff. Up-to-date price lists can be uploaded so costs are always correct. However, the biggest advantage of digital quantity takeoffs is the accuracy and speed that they can be completed. They still need data to be entered manually and a good operator will pick up errors that the software doesn’t recognize, like measuring errors. So, even a digital quantity takeoff is dependent on human interaction, but it can hold much more knowledge, be a lot faster and more accurate than a human being doing manual takeoffs on paper or Excel.

Manual vs digital quantity takeoff

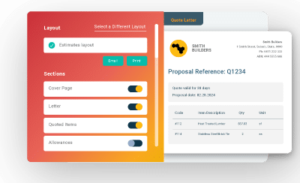

For construction projects, top-quality quantity takeoff software is indispensable. It removes a lot of the complications, is much faster and accurate. It takes a lot of human error out of the process, although it still needs someone to enter data and check for mistakes. A manual quantity takeoff is more time-consuming, relies heavily on skills and knowledge, and any changes can add sufficiently more time to the process. Whereas a digital takeoff can be repeated with relative speed and ease.

A quantity takeoff is an important aspect to any project that has a budget or for making project bids. Without accurate quantity takeoff software, you could find your project under budget – costing you money, or over budget – losing you work.

Want a digital quantity takeoff software that works for you?

Don’t let inaccurate estimates and material costs derail your business. Try Buildxact’s quantity takeoff software today. Get your 14-day free trial or book a demo and see how we can help save your business time and money. We are the construction management and estimating software experts helping builders, contractors, and remodelers get the most accurate quantity takeoffs in the quickest time.