Through the many projects, builds, and your professional experience as a residential builder or remodeler, you might have seen this term floating around.

But familiarity doesn’t mean you can’t be curious about discovering new or better ways to improve your process. So if you’re Googling “material takeoff”, you’re probably trying to figure out one of three things:

- How material takeoffs factor into the full estimating picture.

- Whether your current method is accurate enough for the thin margins in residential builds.

- If there’s a faster, more effective, and more straightforward way than counting items on spreadsheets after hours.

The data, which shows an average cost overrun of 28% across construction projects, means that the knowledge gaps aren’t good news: inaccurate quantity estimates, including materials, are a leading contributor to cost overruns.

In other words, when a builder misses dozens of small fixtures, miscounts drywall, or skips finish details, the ripple effect is felt in their bottom line.

That’s why this guide to material takeoffs will go beyond definition. You’ll learn what a material takeoff actually includes, how it fits into your quote, and how to make it work for your business — not just another menial process.

What is a Material Takeoff?

A material takeoff quantifies and lists all the materials needed for a construction project. It’s essential for keeping home construction projects on track from start to finish.

Home builders use material takeoffs to analyze construction plans and specifications, determining the precise quantities of materials required. This includes everything from concrete, steel, and lumber, to nails, screws, and other small components.

Accurate takeoffs help prevent material shortages and job site delays, keeping projects on schedule and within budget. They also make it easier to compare prices from different dealers, so builders can select the most cost-effective options.

By ensuring only the right quantities are ordered, a detailed takeoff minimizes waste and supports a more sustainable construction process.

Key components of the material takeoff

The goal of a material takeoff is to create a detailed inventory of all required materials for a home construction project (the term “takeoff” originated from manually counting items from blueprints to determine material needs).

A complete material takeoff includes the following components:

- Construction project plans: Digital plans or blueprints compatible with modern digital takeoff software ensure accurate measurements.

- Precise measuring: Digital tools and automated measurements prevent overestimations or underestimations.

- Overall quantity projection: Simple point-and-click commands measure areas, lengths, and volumes to form the basis for material counts.

- Material list and quantities: Construction takeoff software generates accurate material lists, detailing counts such as board feet of lumber and drywall square footage.

- Price fluctuations and waste: As digital takeoffs are faster, builders can factor in potential price changes and material waste earlier, allowing more lead time for purchasing.

- Accurate estimate: Materials and costs are assigned to project phases, completing the overall estimate.

But identifying what’s included in a material takeoff is only half the equation. To build a takeoff that’s accurate, usable, and easy to scale across projects, you need a process that connects those components in a logical flow — from viewing plans all the way through to assigning final costs.

That’s where digital takeoff tools really shine. The visual below walks through each step of the material takeoff process, showing how builders can use these key components to develop a step-by-step approach to conducting smoother and faster construction material takeoffs.

While many builders still rely on manual takeoff methods, intelligent digital tools and AI-powered takeoff software that enable faster, more accurate material takeoffs can give savvy builders a competitive edge. They can merge and simplify the “doing” of many of these components so that they’re more intuitive, automated, and cost-effective.

Best Budget Overruns: Why Material Takeoffs Matter in Residential Construction

Accurate takeoffs are the foundation of every successful build. They directly affect budgeting, procurement, and scheduling — and can make the difference between a smooth project and one plagued by delays or cost blowouts.

When you know exactly what materials you need, in the right amounts, at the right time, you can order efficiently, avoid shortages, and keep jobs on track.

Detailed takeoffs also improve communication and coordination among the project team. By providing a clear, shared materials list, everyone involved – architects, engineers, contractors, and dealers — understands what is needed and when. That means fewer misunderstandings and less time spent chasing updates.

Even small errors in material takeoffs can lead to significant project delays and cost overruns, ultimately impacting profitability. By refining the takeoff process, you can complete projects on time, within budget, and maximize your profits.

Common Takeoff Challenges — and How Material Takeoff Software Can Help

While manual takeoffs remain commonplace in construction estimating, they’re one of the most notorious sources of inefficiency and error on residential projects. From missed materials to hours lost on admin, manual methods make it hard to stay accurate and on budget.

The traditional approach involves working with physical blueprints and manual calculations. Estimators use rulers and scales to measure dimensions from paper plans, recording quantities manually on spreadsheets or takeoff sheets. While this approach may feel familiar, it leaves too much room for error and eats into valuable time that could be spent on-site or with clients.

Below are some of the typical challenges builders encounter when performing takeoffs manually. In the next section, we’ll explore how these challenges can be overcome with automated takeoff software like Buildxact.

- Missed or double-counted quantities — Manually marking up blueprints, drawings, and specifications can lead to overlooking items or counting the same material twice, resulting in inaccurate totals.

- Time-consuming measuring — Scaling and calculating material areas by hand can take hours, especially for large or complex plans.

- Disorganized data and limited visibility — When material lists and supplier data are scattered across spreadsheets and folders, it’s hard to see the whole picture or track updates in real time.

- Manual entry and calculation errors — Entering figures by hand introduces the risk of small mistakes that can have significant cost implications.

- Difficult to update — When material prices change or designs are revised, every figure must be adjusted manually, which is both time-consuming and prone to error.

- Inconsistent results across estimators — Different people use different methods, leading to variations in quantity counts and cost accuracy.

- Delays to quoting and ordering — Manual takeoffs slow down estimate preparation and purchasing, pushing back schedules and affecting job start dates.

Clearly, you need a more effective approach, and modern digital tools offer that pathway. Their features and workflows aim to turn a labor-intensive process into an efficient digital process that’s visible by all, from team members to Clients.

“Industry research affirms that digital tools notably enhance cost estimation, forecasting, and project planning—plus progress tracking—which are vital for SMB builders managing slim margins”

— Digitalization in Construction Report 2024, Royal Institution of Chartered Surveyors (RICS)

Software platforms like Buildxact automate calculations, reduce errors, and speed up the takeoff process. These tools also enhance collaboration by allowing real-time updates and data sharing, improving project coordination and reducing communication gaps.

Faster Takeoffs That Win More Work: Why the Right Software Can Transform Your Material Takeoffs

We’ve seen the many frustrations caused by manual takeoffs. Now, let’s examine how digital tools and automated software can help builders overcome the challenges of manual takeoff processes, transforming a time-consuming and error-prone task into a lever for business growth.

More accurate quantities

Digital takeoff tools measure directly from construction plans, reducing human error and preventing the miscounting of materials. To further enhance this efficiency, tools that leverage AI, such as Buildxact’s digital takeoff assistant, Blu, deploy advanced technology to flag errors, ensuring every quantity is precise and nothing slips through the cracks.

Faster takeoffs, less admin

Replacing manual scaling with point-and-click tools lets builders complete takeoffs in minutes instead of hours. Faster takeoffs mean you can quote more jobs and have time to focus on other activities. For example, an automated platform like Buildxact cuts takeoff time by up to 50% with its AI-driven takeoffs.

“AI-enabled automation and digital tools can augment workforce productivity by helping workers focus on high-value tasks.”

— 2025 Engineering and Construction Industry Outlook, Deloitte

Up-to-date material costs

Software that connects with real-time dealer pricing ensures your estimates always reflect the latest material costs. Accurate pricing protects margins and prevents you from losing out on jobs due to error-strewn proposals.

Consistent, repeatable results

Standardized digital templates enable the consistent application of the same measurement and costing process across all projects. This ensures each job is estimated consistently, regardless of who completes the takeoff, and maintains a reliable baseline for future estimates.

Better visibility into costs

Real-time takeoff data gives you an instant view of total material quantities and spend. Linked dashboards and reporting tools enable builders to see how each item affects overall job budgets, thereby improving cost control from the project’s inception.

Easier collaboration

Cloud-based takeoff software centralizes measurements and plans, allowing everyone involved in the project to access the same accurate information. And with mobile tools like Buildxact’s Onsite construction app, you can access those files from anywhere, at any time. This reduces version chaos and keeps everyone aligned on current quantities and costs.

Fewer delays and surprises

Accurate digital takeoffs help ensure the right materials are ordered on time and in the correct quantities. With connected workflows, builders can anticipate material needs earlier, reducing delivery delays and avoiding costly on-site shortages.

Smarter estimating decisions

When takeoffs connect directly with estimates, builders gain clearer insights into cost drivers and profit margins. In Buildxact, quantities flow seamlessly into the estimating tool, allowing more confident quoting and faster, data-backed decision-making.

Clearly, the right takeoff software can work wonders for the way you perform takeoffs. But to truly realize the benefits of digital takeoff tools, you need to know which features are most important for residential builders

Which features do you (really) need from your construction takeoff software?

Different types of construction businesses will have different needs from their takeoff software. For example, a takeoff for a large-scale commercial project will naturally be more complex than one for a small residential build.

This makes choosing the right platform essential if you want to maximize the benefits and returns of your investment. Intelligent takeoff software like Buildxact is purpose-built for small to mid-sized residential builders, meaning every feature is designed to support the workflows you actually use.

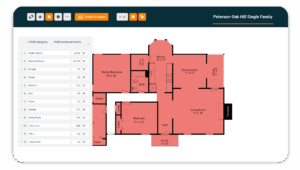

- Digital plans — Upload and scale digital blueprints to measure directly from drawings, replacing paper plans and manual rulers with accurate, on-screen takeoffs that save time and reduce errors.

- AI-automated material calculations — AI-powered tools automatically identify areas, lengths, and volumes, turning plan measurements into precise material quantities that speed up the estimating process.

- Error-checking functionality — Automated review tools flag missing or duplicated items, ensuring every component is counted once and reducing costly mistakes before estimates are finalized.

- Assemblies and templates — Pre-built job templates let builders reuse common tasks and material groupings, improving consistency, accuracy, and efficiency across every takeoff and estimate.

- Real-time pricing integration — Connections with dealer databases provide live material pricing, so estimates stay current as costs change, keeping quotes accurate and protecting profit margins.

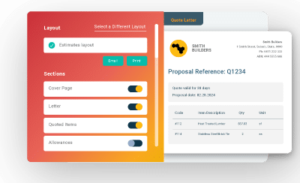

- Customizable estimate generation — Takeoff data links directly into editable estimate templates, enabling tailored, professional quotes that match project scope and client requirements.

- Reusable material libraries — Save frequently used materials, categories, and cost data in digital libraries for quick access, ensuring standardization and accuracy across all future projects.

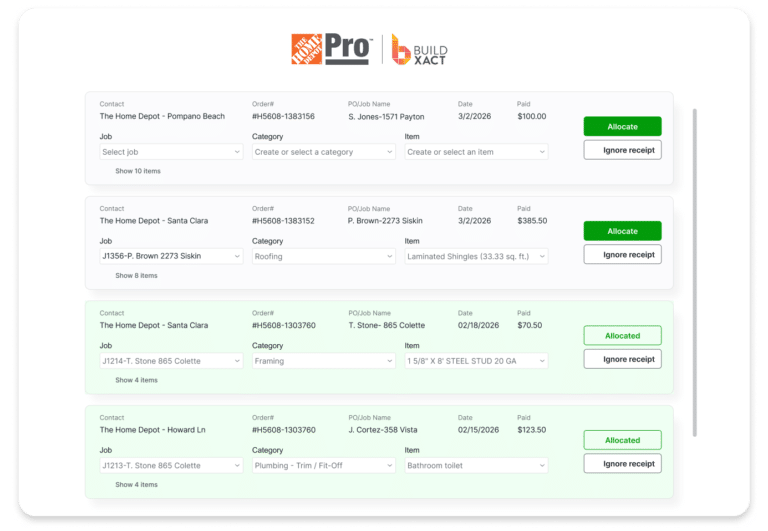

- Dealer collaboration tools — Cloud-based sharing features let builders send takeoffs or material lists directly to dealers for pricing or validation, streamlining communication and reducing ordering errors.

The features above are a helpful starting point when choosing a takeoff platform for residential construction. For more in-depth insights, check out our comprehensive guide to the Best Takeoff Software Options for Builders.

Case Study: How a Small Builder Switched to Smarter Takeoffs With Buildxact

VW Building Projects streamlined their workflows and boosted efficiency by leveraging Buildxact’s advanced takeoff and estimating features. The platform helped them speed up takeoff processes, reduce estimating errors, and enhance productivity.

Using Buildxact’s AI-automated measuring tools, handling PDF takeoffs became faster and easier, saving time and resources for critical aspects of their projects.

With Buildxact’s easy-to-use takeoff software, VW Building Projects can now reliably develop and use accurate estimates, as well as simplified material purchasing, thereby enhancing their profitability and client satisfaction.

The Future of Material Takeoffs: How AI and New Technology are Changing the Takeoff Game

Advancements in construction technology are enabling a more integrated, data-driven, and collaborative approach to material takeoffs, designed to improve processes and enhance project outcomes.

AI and automation have completely reshaped the way digital material takeoffs are conducted. AI tools analyze complex project data, automatically identify and measure materials, and predict potential waste or cost overruns. This kind of innovation is evident in tools like Buildxact’s AI-powered takeoff and estimating assistant, Blu, which delivers precise, error-free takeoffs in half the time.

Other technological innovations, such as augmented reality, drones, and robotics, promise to increase accuracy and efficiency in material takeoffs further, leading to more sustainable construction practices.

“Software solutions that incorporate AI and ML capabilities can provide builders with valuable insights, allowing them to make data-driven decisions and optimize project outcomes.”

— Home Builder Software Market, Data Intelo

Swap Inaccurate Manual Takeoffs With Precise Bids That Win More Jobs

Manual takeoffs make it harder to compete. Each delay or missed detail reduces accuracy, extends quoting time, and limits the number of jobs you can pursue.

Buildxact takeoff software simplifies the process through AI-driven automation and accurate digital measurements. Every takeoff is completed faster and with clear, consistent results that protect your margins and strengthen client confidence.

Experience faster, more accurate estimating and submit quotes that help you secure more of the right work. Start your free 14-day trial today or book a demo to discover the Buildxact difference for yourself.